Manufacturing Transformations

Operation

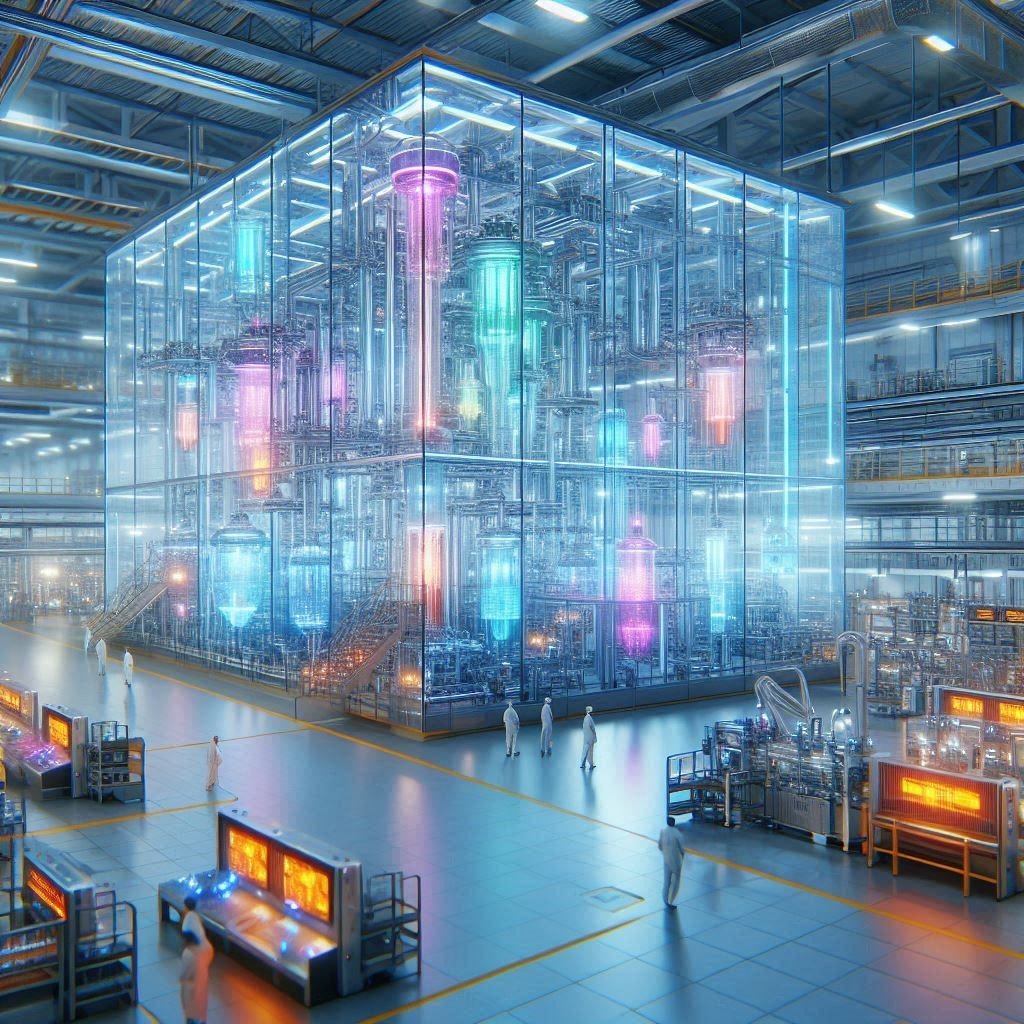

The process of manufacturing is quite extensive, in a nut shell it has to do with converting raw materials into finished products through the use of tools, labor, machinery, and chemical processing. Manufacturers have introduced the concept of using advanced manufactoring technology into their operation in order to improve operational efficiencies and enhance safety for workers while at the same time delivering cost-effective solutions.

Initiative

On December 2022 a project known as AI MAnufacturing Testing and experimenTation network For EuRopean industrieS (AI-MATTERS) was initiated by The French Alternative Energies and Atomic Energy Commission (CEA), "Commissariat à l'énergie atomique et aux énergies alternatives" a public research organization that focuses on scientific, technical, and industrial areas.

Researchers who initiated the project aimed to develop a more adaptable production system through the utilization of AI, robotics, and intelligent systems, thus increasing the flexibility of the European manufacturing sector.

Challenges

So far the project has been picked up by other European countries such as Germany, France, Italy, Greece, the Netherlands, and Czech Republic. Each country has focused on facing specific challenges such as:

Factory level optimization: Has to do with “using advanced technological practices such as automation, data analytics, real-time monitoring, and ensuring a seamless and optimized production workflow”, By doing so it would be possible to “improve the process of streamline operation, minimize waste, and boost productivity”.

Circular economy: Focuses on minimizing waste by designing long lasting, reusable, and recyclabe products. The goal is to “create a closed-loop system where materials are continuously repurposed, reducing environmental impact”.

As of now AI-MATTERS continues to be on the testing and experimentation phase. However, there have been a record of promising developments.

Sources: